Safety is a key priority of the Oil, Gas, and Energy Sector, which is why remote site inspections comprise a significant chunk of energy companies’ operational expenses. Given a shifting political and economic landscape, many energy companies are looking for ways to streamline operations and reduce expenses, while maintaining safety and regulatory compliance. And that is why they are investing in remote site inspections with Optical Automation.

Let’s take a look at the status quo.

OGE companies have many upstream sites, often in remote areas. State and federal laws require that these sites be inspected on a regular basis. Some companies have an “every site, every day” inspection policy; others inspect once a week, once a month, or whatever is prescribed by their jurisdiction(s). Based on these rules, a technician drives around to each site, assesses the overall condition of the site, and looks for signs of leaks, theft, damage, trespass, etc.

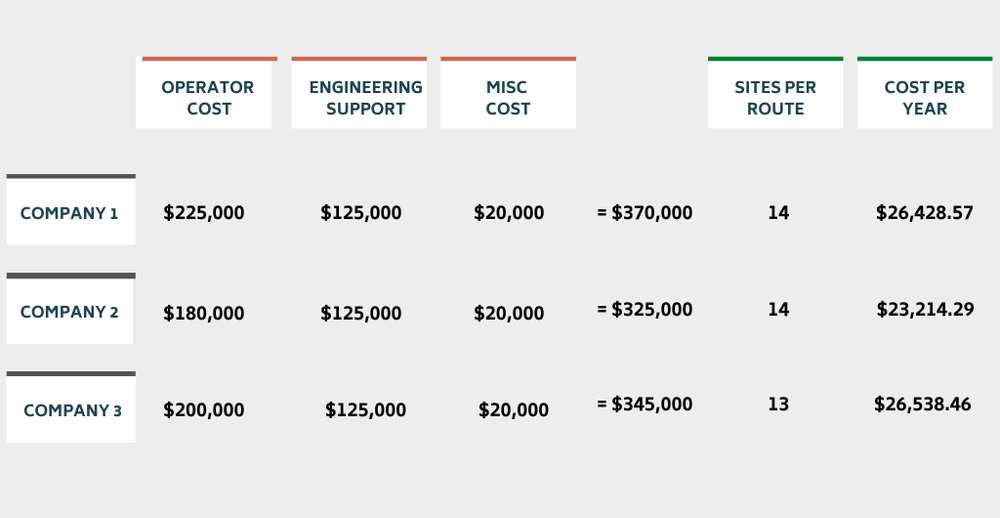

An operator might be responsible for 13-15 locations and spend anywhere from 30 seconds to 30 minutes at each site; these sites can be a couple to 30 minutes apart. OGE operators spend anywhere from $23,000 to $26,000 per year/per site inspecting remote sites. In most cases, there are no issues and nothing to fix so the time, travel expense, and manpower are wasted resources. When these sites are low producers, the cost of inspections can very well exceed any profits. However, these sites are typically maintained indefinitely due to the exorbitant cost of decommissioning them per state and federal requirements.

How can OGE operators maintain remote sites more efficiently? Remote Site Inspection (RSI) with Optical Automation is the solution.

Key benefits of RSI:

- Provides 24×7 coverage of all remote sites

- Simplifies compliance with state and federal inspection requirements

- Supplements manpower and enables workers to be more efficient – going only where needed, when needed

- Decreases time to identify and respond to any detected issues

- Minimizes potential penalties and fines due to identified leaks, flares, etc.

- Reduces “window time,” i.e, the time spent driving from site to site

- Reduces fuel expenses required to visit each remote site

- Decreases carbon footprint of operations

- Enables predictive maintenance

- Reduces annual maintenance expenses

- Increases uptime

So what’s the ROI?

Twin Eagle customers who implemented Remote Site Inspections using Optical Automation were able to realize a return on their investment within 10 -14 months. The chart below shows the average expenses before RSI. The average cost of a single Optical Automation system is lower than those expenses, allowing savings within the first year and elimination of those expenses in future years.

Now is the time to optimize your remote site inspection process and reduce operational expenses. Let’s talk about how Optical Automation can help you.